When you think of blockchain, you probably think of Bitcoin or crypto wallets. But the real money-saving power of blockchain isn’t in trading coins-it’s in how it’s quietly fixing broken supply chains. Companies are cutting costs by 20% to 40% just by switching from paper receipts and spreadsheets to a shared digital ledger. And it’s not hype. It’s happening right now in food, pharma, and auto manufacturing.

What’s Actually Saving You Money?

The biggest cost killers in supply chains aren’t fuel or labor-they’re the invisible ones: paperwork, delays, mistakes, and disputes. Every time a shipment moves from a factory to a warehouse to a store, someone has to update records, check inventory, match invoices, and wait for approvals. That’s 40 to 60 hours a week per team just reconciling data across different systems. Blockchain wipes that out. Instead of five different companies keeping their own versions of the same shipment record, everyone sees the same version in real time. No more arguing over who shipped what, when, or if the temperature was right. That’s not just convenience-it’s direct cost reduction. Deloitte found blockchain cuts reconciliation costs by 20-30% across procurement, production, and delivery. For a company spending $50 million a year on supply chain admin, that’s $10-15 million saved annually.Smart Contracts: The Automatic Payroll for Your Supply Chain

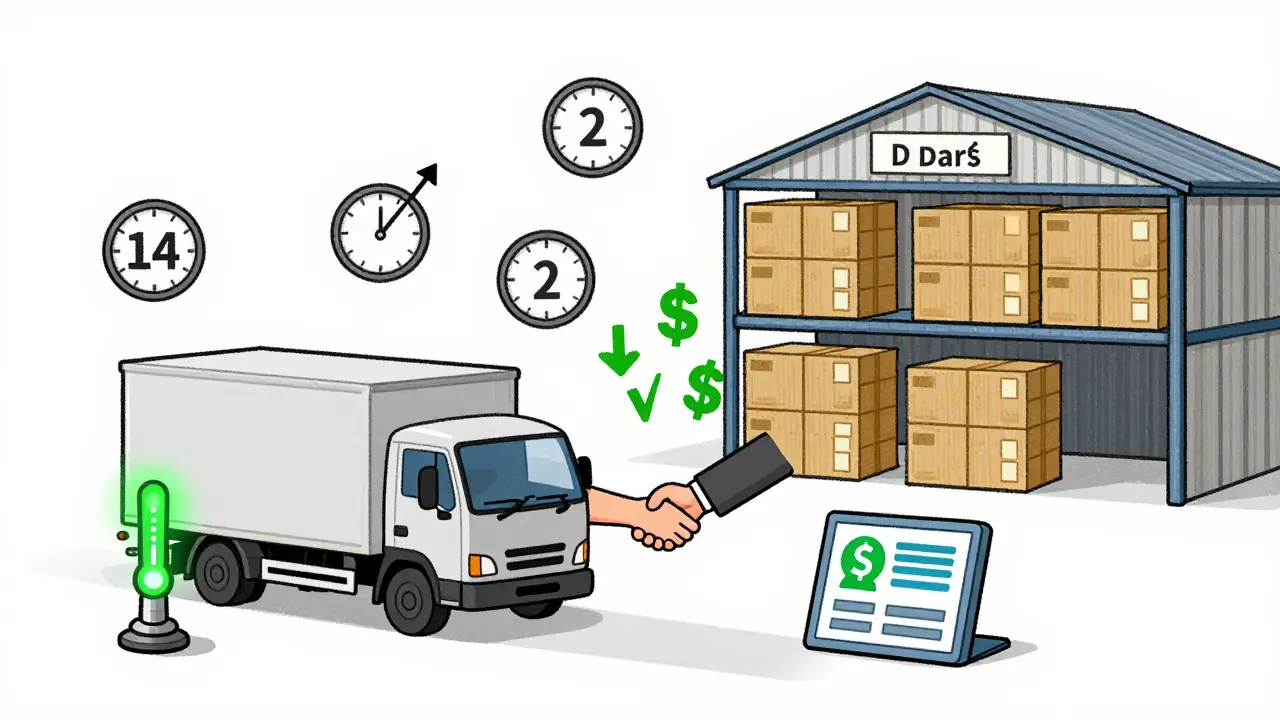

Imagine this: a truck arrives at your warehouse with 1,000 boxes of medicine. The temperature sensors inside the trailer show it stayed between 2°C and 8°C the whole way. No one has to call, email, or sign anything. The system checks the sensor data against the contract, confirms it’s good, and instantly releases payment to the carrier. That’s a smart contract in action. Oracle’s case study with Tracifier showed food processors cut processing costs by up to 40% because quality checks went from days to minutes. Payments that used to take 14 days now clear in 48 hours. One logistics manager on Reddit reported saving $185,000 a year just by automating invoice approvals. That’s not theoretical. That’s payroll you no longer need. Smart contracts also cut down on fraud. In pharma, counterfeit drugs cost the industry $200 billion a year. With blockchain, every pill’s journey-from factory to pharmacy-is recorded. If something looks off, you trace it back in seconds. The FDA says recalls used to cost $10 million per incident. Blockchain cuts those numbers by 60-70% by stopping bad batches before they leave the warehouse.Real Numbers from Real Industries

Let’s get specific. This isn’t guesswork. Here’s what’s working:- Food supply chains: Tracifier users cut costs by 40%. Why? Less waste. Faster recalls. Fewer spoiled goods. A single spoiled pallet used to mean losing $20,000. Now, you know exactly which pallets are affected-and which ones are safe.

- Oil and gas: The University of Tennessee documented a $100 million annual drop in freight spend. How? Automated shipping docs cut disputes and delays. No more waiting for customs to manually check 240 paper forms per shipment.

- Pharmaceuticals: Inventory shrinkage dropped 15-25%. That’s product you no longer lose to theft, mislabeling, or misplacement. Gartner found 68% of companies saw ROI within 18 months.

- Automotive: Inventory tracking costs fell 35% compared to old barcode systems. Workers used to spend 15-20% of their time just checking stock. Now, sensors and blockchain update everything automatically.

Why Some Companies Fail (and How to Avoid It)

Not everyone wins. A retail company in the Midwest spent $750,000 on blockchain, then quit after 14 months. Why? They tried to automate everything at once. They didn’t start small. They didn’t train their team. They expected magic. The right way? Start with one problem. Pick one high-cost, high-friction process-like invoice matching or cold-chain monitoring. Pilot it with three partners. Keep it simple. Oracle recommends pilot projects cost $50,000-$150,000. That’s a fraction of the $250,000-$500,000 it costs to roll out company-wide. The biggest failure point? Data standards. 78% of companies in Deloitte’s survey struggled because suppliers used different formats for dates, product codes, or weights. Fix that first. Use open standards like Hyperledger Fabric, which scores 4.2/5 for clear documentation. Avoid vendor lock-in. Pick platforms that play nice with your existing ERP systems-no need to replace everything.Who’s Really Using This?

You won’t find small businesses running blockchain supply chains yet. Gartner says 82% of users are companies with over $1 billion in revenue. Why? It takes scale to justify the cost. But that’s changing. Consortiums are making it cheaper. TradeLens, though shut down in 2023, proved that when 10 companies share the cost of one blockchain network, individual savings jump 40-60%. Now, groups like the Blockchain in Transport Alliance (BiTA) are building industry-wide standards. Early adopters saw implementation costs drop 22%. Regulations are pushing adoption too. The EU’s Digital Product Passport and the FDA’s 2024 Drug Supply Chain Security Act require full traceability for food and medicine. If you don’t use blockchain, you can’t sell. That’s creating $7.2 billion in forced spending by 2026-not optional.

This is why America needs to lead in tech, not let China dictate the future. Blockchain isn't just fancy tech-it's national security. We're handing our supply chains to foreign actors if we don't adopt this now.

The real paradigm shift here is the immutability layer enabling trustless interoperability across multi-party ecosystems. Hyperledger Fabric's permissioned consensus model reduces Byzantine failure risk while enabling atomic settlement-a game-changer for B2B reconciliation workflows.

YESSSS this is what I've been saying for years! 🙌 No more lost shipments, no more paper trails, no more screaming at your logistics guy at 2am. Blockchain is the unsung hero of modern business. Let's get everyone on board-small biz too!

I'm sorry, but this sounds like a government-backed surveillance scheme disguised as efficiency. Who owns the ledger? Who controls the keys? And how do we know this isn't just another way for corporations to track every movement of every product-and every person involved?

20-40% savings my ass. You think big corps are saving money or just forcing suppliers to pay for the tech? And don't get me started on how they'll use this to cut jobs. Blockchain ain't magic it's just another tool for the 1% to squeeze the 99%

bro this is wild i just saw a trucker use a tablet to scan a qr code and poof payment went through instantly. no forms no waiting. this shit is real. we need this everywhere

Everyone ignores the human cost. People who used to check paperwork are now unemployed. This isn't progress it's automation with a shiny name. And don't tell me about savings when families are losing livelihoods

In Nigeria we struggle with customs delays of 3 weeks. If blockchain can reduce this even by half it would transform our export economy. We need international support to adopt these standards not just for rich countries

You're missing the bigger picture. The real advantage isn't cost reduction-it's the shift from reactive to predictive logistics. When you integrate real-time sensor data with immutable ledgers and machine learning, you're not just tracking shipments-you're anticipating bottlenecks before they occur. This is the foundation of autonomous supply chain ecosystems, which will eventually render human middlemen obsolete. And yes, that includes your cousin who 'handles paperwork' at the warehouse. He's not a victim-he's a relic.

It's funny how we call this innovation but it's really just replacing human trust with algorithmic trust. We used to rely on relationships and handshakes. Now we rely on code. Is that progress? Or just a different kind of loneliness?

I work in auto parts and we started with just one supplier for coolant tanks. Reduced errors by 70% in 3 months. No drama. No yelling. Just clean data. It’s not perfect but it’s way better than before.

While the technical merits are compelling, one must consider the ethical implications of decentralizing accountability. The absence of a central authority does not equate to increased transparency-it merely redistributes responsibility without recourse. Regulatory frameworks lag behind technological adoption, creating significant legal exposure.

Start small. Seriously. Pick one pain point-like temperature logs for vaccines-and try it with two partners. No need to overhaul everything. I helped a local pharma distributor do this last year. Cost: $80k. Saved: $220k in a year. You don't need to be Amazon to make this work.

Another tech bro fantasy. 82% of users are billion-dollar companies because it's too expensive and complicated for anyone else. This isn't democratizing anything. It's locking out small players. And don't even get me started on how many of these 'blockchain' systems are just glorified databases

I read this whole thing and all I could think was... who's gonna fix it when the blockchain breaks? You can't just call Apple support for a distributed ledger. This is one glitch away from a $500M disaster and everyone's acting like it's magic

I've seen this work in practice. A small farm co-op in Iowa used it to track organic produce. Customers could scan a QR code and see exactly where their lettuce came from, who picked it, and when. Sales went up 30%. People trust what they can see. This isn't just tech-it's storytelling.

The real bottleneck isn't the tech-it's the legacy ERP systems. I've seen companies spend $2M trying to integrate blockchain with SAP R/3 and end up with a Frankenstein system that crashes every Friday. You can't just slap a ledger on top of 1998 software and call it innovation.

Everyone talks about savings but no one mentions how much training it takes. My team spent 6 weeks just learning how to read the dashboard. Half quit. The rest still don't trust it. Tech doesn't fix culture problems

We're not just tracking shipments-we're rewriting the social contract of commerce. Every barcode is a whisper of power. Every timestamp a monument to control. What happens when the ledger decides who gets paid? When the algorithm denies a farmer's claim because a sensor 'glitched'? This isn't efficiency. It's digital feudalism.